Cumbria is in NW England and is a part of the shire! Hmm this must be good!

Cumbria is in NW England and is a part of the shire! Hmm this must be good!I've been hounded by a fellow blogger about not blogging. Well, I didn't really have anything to blog about so I thought I'd run through the steps of brewing a beer extract kit for those who don't know how to do it. You can stop asking for posts now Jack.

Step 1. Obtain ingredients and tools.

I was fortunate and blessed to receive 2 beer kits from my mom and stepdad for Christmas. Yippee! I also use food grade utensils (no wood) and 5 gallons of good clean water. I usually use jugs from the store, but opted for tap. I like my tap water so I thought I'd try it for a change...and it's cheaper! All brewing ingredients were purchased at www.NorthernBrewer.com whom I highly recommend.

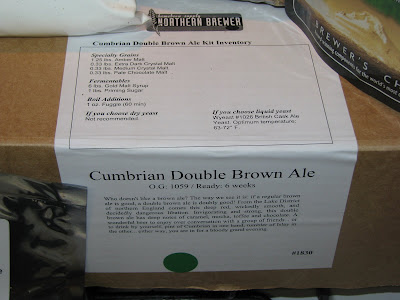

Kit: Cumbrian Double Brown Ale

Step 2. Activate Yeast

This kit comes with Wyeast's British Cask yeast. From my understanding the package contains a nutrient rich inner package that is sitting in a water yeast mixture. Pop the inner package and let it sit for at least 3 hours; it swells as it sits. I like to give it a shake every now and again; store it someplace warm, but not hot.

Wyeast 1026 PC British Cask Ale

A great yeast choice for any cask conditioned British Ale and one that is especially well suited for IPA’s and Australian ales. Produces a nice malt profile and finishes crisp & slightly tart. Low to moderate fruit ester producer that clears well without filtration.

Attenuation 74-77%

Alc. Tolerance 9%

Flocculation medium/hIgh

Temperature Range 63-72°F (17-22°C)

Step 3. Clean and Sanitize!

There is a difference. The first rule to good beer is sanitization. Just for good measure clean and sanitize everything, especially the utensils you will be using and your hands... over and over at every step.

Step 4. Let's make some wort!

I use about 1.5 gallons of water set to boil in a stainless steel kettle (some use aluminum). Once the water reaches about 150-160ºF I put the steeping grains in to steep for 15 minutes. This kit has a LOT of steeping grains.

At this point I like to take the Malt Extract and place it in a pan of hot water and layered on the bottom with paper towels. I then bring the water up to a nice high heat to lower the viscosity of the extract; you have to make sure the seal is popped and the cap is loose.

While waiting for the 15 minute mark it's a good time to have some inspiration while you are waiting.

After 15 minutes I remove the bag, let it drain, and then carefully squeeze the bag to get some of the excess moisture out. I then toss it in the trash and turn up the heat to get the kettle to boil. I think it's called a wort at this point (unfinished beer).

Once it comes to a boil, I turn off the heat and remove the kettle from the burner. This is when the fermentables are added in; the sugars the yeast are going to live off of: the 6#'s of Gold malt extract and 1# of corn sugar. I like to use a nice flat spatula to scrap the bottom of the kettle to make sure the sugars don't stick (and later burn) as I mix them in.

Now I return the kettle to the burner and bring it up to a boil.

Once it starts to boil you have to be very careful of a boilover, that can be VERY, VERY messy. When it is boiling add the bittering hops: 1 oz of Fuggle Pelletized Hops, Alpha 4.6% (60 min).

There is usually an extreme boil over danger here so be careful! I had to turn down the heat immediately after I added the hops. It was actually above the top of the kettle but it sank back down as soon as I was able to get the heat turned down. See the hop pellet in mid air?

This boils for 60 minutes. In some kits you may add some hops in the last 5-30 minutes for aroma, but not this recipe. Now is a good time to make sure your fermenter and the rest of your supplies are sanitized. I generally use this time to watch a movie on the laptop or read a good book while enjoying the inspiration.

As it nears the 40 minute mark I like to fill the sink about 2/3 full of COLD water for the ice bath. You need to cool the wort as fast as possible to about 70ºF, 20 minutes is pretty good. The faster you cool it, the clearer is will be as a finished product. Also, it has to cool down before the yeast is added or it could kill them. I like to brew in the winter because the water is waaaay colder coming out of the faucet. Then I add my frozen gallon jug to the sink to thaw. Once it thaws a bit I cut open the jug to let the ice out and ice pick about 10 minutes before the end of the boil time; I also keep other ice on hand to keep the water cool.

T-00:00:01 and Stop! Ok, now that the time limit is up I cut the burners and make sure my lid is sanitized. Lid on, lift, and insert into the cool bath. I like to swirl the wort to help cool the middle. I also like to CAREFULLY swirl the cool water around the ketlle. I usually use a couple of bags of cubed ice, but I forgot and well...here we are instead. Over all I think that it works rather well in the winter with out needing extra ice.

Once the temp reached a low point, or was close to it, I poured 3 gallons of cool water in the fermenter. I then set up my handy dandy strainer to keep all the grain and hops particles out of the fermenter and out of my beer bottles. Many people like to use a wort chiller to cool their beer and leave the particles, or cold break, but since I am too cheap to make or buy a cooler, I'll just have to make do.

Now that I've reached about as low as I can get in my current set up I am going to filter the wort through the strainer into the fermenter. Since the strainer is small and fills up fast I have to do it in 3 different pours. Pour, shake, empty, repeat.

Now is a good time to aerate the wort. I like to froth it with my spoon I've been using all night.

Next is pulling a sample so I can check the gravity of the beer. I use a sanitized siphon to place it into the beaker for my hydrometer testing later.

Now I need to pitch my yeast. I've already sanitized it and my scissors so all I have to do it carefully release the pressure and cut a large enough hole to empty the contents without dropping in the inner pouch. I cut the entire bag open so you could see what it looks like.

Pitch it in!

Now I snap my sanitized lid on top, fill the sanitized air lock (allows gas out but not in) and store it in a cool dark area between 63-72ºF.

Now I have to wait about 2 weeks before I stage it into my racking bucket to put into bottles. I'll update you when that happens. Overall it will take about 6 weeks for the product to be ready for consumption.

The gravity measured at 1.058, very close to the ending gravity.

Hope you enjoyed....though probably not as much as I will!

ps- I had many problems with blogger while doing this so I am not going to "polish" it. If there is a mistake, deal with it. I'm done doing blogs this picture heavy.

16 comments on "Northern Brewer's Cumbrian Double Brown Ale"

Nothing worth blogging about you say? That has never stopped me before.

Why are you boiling a tuque???

tuque? a heavy stocking cap worn in Canada? I'm not... What you may be looking at is the steeping grains in a cotton bag; think tea bag full of grain.

Well I think the only way I can possibly know that for sure... is to try the beer when it's ready.

:-P

Very nice!

That yeast sounds good...I need to do some British bitters as session beers again, but all I have on hand is pilsner malt, so its German bier, and maybe an American Pale Ale or two, for the moment.

Looks like textbook extract brewing!

Just for the record, I found this post rather facinating and well done. I just like to get the jabs in first and then compliment later.

I found it long and tedious and did not really read past the first paragraph. I didn't even really look at the pictures after the fourth of fifth one. However, if I ever need step by step instructions to home brewing, I will definitely come back to this post!

That is just what I would expect from you Coder. But, to be fair, I give your posts about the same amount of consideration!

yummy, i want some.

I know you do- that's why I threw that jab! But at least in my case, it was legitimately out of disinterest and not from tiring of looking up words in the dictionary. :-P

You look up words in the dictionary? Yikes, I didn't know it was that bad...

Your mom goes to college!

Nice comeback... your mom goes to college!

HEY!!

jinx

My mom didn't go to college. Well, she went to nursing school, does that count?

"Dorothy Mantooth is a SAINT!!"

"Ok ok, let's leave the mothers out of it."

Post a Comment